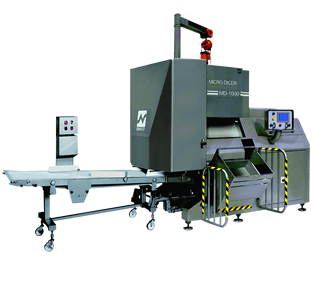

MICRO DICER

The Micro Dicer is our original machine to cut meat finely, which can cut a frozen meat block finely by the cutter without giving any pressure to the meet. It is an epoch-making machine that can cut the material in small pieces like a shape cut with a kitchen knife without spoiling the meat taste and texture. The Micro Dicer is our registered brand name.

- MD-350

- MD-500

- MD-1000

Changes Tastes and Textures of Meat Better

No pressure is given to meat, which minimizes a rise in the product temperature, and enables to cut the meat as it is without any fat separation.

Tastes and textures of meat change better in dumplings, hamburger steaks, shaomai, spring-sown, etc.

(Applicable material: beef, pork, chicken, cheese, etc.)

"Step-Cutting" prevents a meat quality from a damage.

No pressure is gives to the meat, which minimizes a rise in the product temperature, enables to get meat fractions cut finely, as they are, without any fat separation.

Even cut volume

Meat fractions of the even volume can be obtained by knives positioned spirally on the disk.

The cut length can be changed.

Adjustment can be done by changing a rotation rate of the impeller knife. (Inverter control)

Multi-purpose use is possible.

Cutting cheese is applicable as well.

Convenient and handling excellent

Even a large meat block such as 60 lbs can be processed as it is and fed easier using a lifting device.(MD−1000)

Sufficient safety counter-measure

Interlocking safety covers at the cutting part and the material feeding part, and a motor with brake is equipped.

| Model | MD-350 |

|---|---|

| Power supply | 3-Phese 200V 2.2/1.5/0.04/0.2 kW |

| Capacity | 90〜440 kg/h (Theoretical value) |

| Tub Capacity | |

| Dimensions: (Width×Depth×Height) | 700×1665×1258mm |

| Weight | 585 Kg |

| Remarks | Max. meat block dimensions :75(W)×115(H)×300(L)mm Adequate temperatures of meat block:-5〜-8°C. Cut size:2〜10mm |

Changes Tastes and Textures of Meat Better

No pressure is given to meat, which minimizes a rise in the product temperature, and enables to cut the meat as it is without any fat separation.

Tastes and textures of meat change better in dumplings, Hamburg steaks, Chaotsu, Shaomai, Spring-sown, etc.

(Applicable material: beaf, pork, chicken, cheese, etc.)

"Step-Cutting" prevents a meat quality from a damage.

No pressure is gives to the meat, which minimaizes a rise in the product temperature, enables to get meat fractions cut finely as they are without any fat separation.

Even cut volume

Meat fractions of the even volume can be obtained by knives positioned spirally on the disk.

The cut length can be changed.

Adjusting can be done by changing a rotation rate of an impeller knife. (Inverter control)

Multi-purpose use is possible.

Applicable for cutting cheese as well.

Convenient and excellent handling.

Even large meat block such as 60 lbs can be processed as it is and fed easier using a lifting device.(MD−1000)

Sufficient safety counter-measure

Interlocking safety covers at a cutting portion and material supply portion, and motors with brakes are equipped.

| Model | MD-500 |

|---|---|

| Power supply | 3-Phase 200V 3.7/3.7/0.05/0.45 kW |

| Capacity | 215〜1150 kg/h (theoretical value) |

| Tub Capacity | |

| Dimensions: (Width×Depth×Height) | 1030×2134×1515mm |

| Weight | 1140 kg |

| Remarks | Max. meat block dimensions : 180(W)×100(H)×550(L)mm Adequate temperatures of meat block : -5〜-8°C. Cut size : 2〜10mm Conveyor : Option |

Changes Tastes and Textures of Meat Better

No pressure is given to meat, which minimizes a rise in the product temperature, and enables to cut the meat as it is without any fat separation.

Tastes and textures of meat change better in dumplings, Hamburg steaks, Chaotsu, Shaomai, Spring-sown, etc.

(Applicable material: beaf, pork, chicken, cheese, etc.)

"Step-Cutting" prevents a meat quality from a damage.

No pressure is gives to the meat, which minimaizes a rise in the product temperature, enables to get meat fractions cut finely as they are without any fat separation.

Even cut volume

Meat fractions of the even volume can be obtained by knives positioned spirally on the disk.

The cut length can be changed.

Adjusting can be done by changing a rotation rate of an impeller knife. (Inverter control)

Multi-purpose use is possible.

Applicable for cutting cheese as well.

Convenient and excellent handling.

Even large meat block such as 60 lbs can be processed as it is and fed easier using a lifting device.(MD−1000)

Sufficient safety counter-measure

Interlocking safety covers at a cutting portion and material supply portion, and motors with brakes are equipped.

| Model | MD-1000 |

|---|---|

| Power supply | 3-Phase 200V 7.5/5.5/0.1/0.75×2 units kW |

| Capacity | 390〜2650 kg/hour (Theoretical value) |

| Tub Capacity | |

| Dimensions: (Width×Depth×Height) | 1790×2520×2860mm |

| Weight | 2900 kg |

| Remarks | Max. meat block dimensions 400(W)×180(H)×550(L)mm Adequate temperatures of meat block:-5〜-8°C. Cut size : 2〜10mm |

※All specifications are subject to change without notice to improve the product.