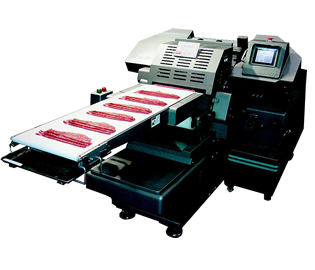

SLICER

Slicer is a machine which can slice meat. Many of other companies�fconventional machines adopt a round edge or a hatchet-shape edge, but our machines adopt the Band Knife ( a belt-shape edge) having an excellent cutting performance.

- AZ-340

- AZW-320

- AX-320

- TS-490

- AXY-200

Bending Slicer, AtoZ, is a slicer targeting at a later generation, which can slice pork's short loin, shank, etc. in a plus temperatures range, doubling in two, aligning in two-row and picking up on the belt conveyor.

��Features��

�@A meat block is securely held by an intermittent work of the pusher plate and the feed belt. Then Band Knife slices up a meat flake from a meat block with a unique swing movement of the meat feed table while the meat block is contacting the support plate. Therefore, the softened meat in a plus temperatures range can surely be cut as well.

Also, as the meat clicking to the edge is decreased, meat loss can be minimized.

�APork short loin and ham in plus temperatures range (the suitable temperatures range to cut is + 2��C. to + 3��C.), which has never been put into a practical use, are thinly sliced. Then, the sliced meat thinly is exactly doubled in two by the unique folding device, and is discharged aligning on the belt conveyor according to a set distance.

The folding direction and the top or bottom position of a fatty surface can be determined without restraint.

The product is hygienic because of decreasing a manual touch, and also keeping of its freshness can be improved.

�BThe folding position is automatically controlled in accordance with a height of the meat block after it has once been set; therefore, the readjustment is not required during operation. However, an initial setting-up and a fine-tuning during working are possible by the liquid crystal control panel in operation.

�CThe folding device has a mechanism retreating bended skewers from the belt conveyor surface after completion of the positioning work. When the material around the connecting position is fed for cutting, the sliced meat thinly will be fed out without folding on the belt conveyor. Therefore, continuous operation is maintained and the efficiency work becomes possible.

�DThe arrangement distance of the sliced meat after folding can freely be set. A good appearance will be taken when the sliced and folded meat is arranged on a plastic tray as it is.

�ETwo-row slicing at one time for short loin and ham, etc. is possible.

�FA continuous operation can be done if materials are subsequently supplied.

�GCube-Rolls, etc. which are easy to tear also can thinly be sliced unless their size is bigger than the holder size.

�HCutting, folding and discharge conveyor parts can be separated and sled in one-touch; therefore, cleansing and maintenance can be made in ease.

The feed conveyor and the discharge conveyor can easily be mounted and dismounted.

�IThe band Knife is always kept sharply by a grinding device that is intermittently working during operation, and cleansed by the cleaning device into which the scraper and both water dripping and air blowing are incorporated. Therefore, the sliced surface of the meat is fine because of minimizing stains which come from grinding powder, oil fat flakes, etc.

A labor saving and a safety securing were achieved by mechanization of a manual work.

Product efficiency was increased by making a temperature control easy.

A commodities value of the sliced meat thinly was improved.

Slicer for Pork Cutlets is a custom-made product based on your own requirements. Please contact us by e-mail.

| Model | AZ-340 |

|---|---|

| Power supply | 3-Phase 200V 1.64 kW |

| Capacity | 2-row-cut 100 pieces/minute |

| Tub Capacity | |

| Dimensions: (Width�~Depth�~Height) | 1410�~2470�~1175mm |

| Weight | 950�@kg |

| Remarks | Dimensions of possible slicing material : 160�iW�j�~100�iH�j�~600�iL�jmm Temperatures of possible slicing : -1�`5��C.�i2�`3��C. is suitable�j Adjustable thickness of slicing : 1�`20mm Air supply source pressure : 0.5�`1.0�@MPa Air consumption volume : 400�@liters/min Water : Connecting to a water piping |

This machine is Bending Slicer of which sale is very popular, succeeding the excellent performance of AtoZ as it is, and enhancing a multiplicity of uses much more. It is capable of slicing a meat of 320mm wide that the AtoZ can not cut, doubling in two and aligning it on the belt conveyor.

Excellent slicing performance

Even though it is a soft meat in a plus temperatures range, slicing thinly can be done steadily.

As scrapers always keep a blade surface clean, a fine cut surface can be obtained.

the band Knife is automatically ground, therefore a sharp edge can be kept.

As the positioning plate for cutting meat is equipped, the thickness of slicing can accurately be set up and higher yield ratio can be taken.

Easy handling

The sliced meat thinly will be discharged aligning on the belt conveyor just to supply the meat block. Therefore, greater safety handling of the sliced meat can be performed in comparison with a conventional direct manual handling, and any special technique and skill are not required.

Supply of the meat block can continuously be done.

A thickness of the meat along with its folding position can simply be established with touching the liquid crystal control panel.

Easy cleansing without fail

A belt conveyor for discharging can be separated with one-touch.

All component parts where meat goes through except electrical parts can be cleansed by water.

Safety device

The pulley cover for Band Knife and the safety cover are both equipped with an inter-lock system. Sensors are incorporated to detect circumstances in case of coming-off of the Band Knife and braking -off of its edge, and then to stop the machine.

Enlarged cutting surface

Materials having maximum 320mm wide and 180mm high can be treated. Discharge of the sliced meat without folding is possible as well.

An adjustment range of slicing thickness is enlarged.

The slicing can be adjusted within the thickness from 1mm to 25mm.

The efficiency control is possible.

Slicing times can be coordinated in accordance with the working pattern from 10 to 50 times per minute.

| Model | AZW-320 |

|---|---|

| Power supply | 3-Phase 200V 2.09 kW |

| Capacity | Slicing driving : 10�`50�@times/minute�@�@ Folding driving : 10�`25�@times/minute |

| Tub Capacity | |

| Dimensions: (Width�~Depth�~Height) | 1410�~2670�~1255mm |

| Weight | 980Kg |

| Remarks | Dimensions of possible slicing material : 320�iW�j�~180�iH�j�~600�iL�jmm Temperatures of possible slicing : -1�`5��C.�i2�`3��C. is suitable�j Adjustable thickness of slicing : 1�`25�@mm Air supply source pressure : 0.5�`1.0�@MPa Air consumption volume : 350�@liters/min |

Raw materials can continuously be fed, and a sliced meat is neatly arranged on the belt conveyor. In case of using a conventional machine having a knife besides the band knife, the productivity can significantly be improved by minimizing a volume of lower grade (for mince) meat or waste meat if this AtoX is adopted. Our machine for demonstration h as successfully achieved as high 99% yield ratio at its test operation.

as successfully achieved as high 99% yield ratio at its test operation.

| Model | AX-320 |

|---|---|

| Power supply | 3-Phase 200V 1.95 kW |

| Capacity | 20�`60�@times/minute |

| Tub Capacity | |

| Dimensions: (Width�~Depth�~Height) |

1410�~2670�~1255mm |

| Weight | 980Kg |

| Remarks | Dimensions of possible slicing material : 320�iW�j�~180�iH�j�~600�iL�jmm Temperatures of possible slicing : -1�`5��C.�i2�`3��C. is suitable�j Adjustable thickness of slicing : 1�`25mm Air supply source pressure : 0.5�`1.0�@MPa Air consumption volume : 300�@liters/min |

This is an ideal machine for processing plants that produce pork cutlets for frozen foods, which solved problems in a conventional Slicer.

Stable thickness of slicing

It was not possible for Slicers, which are equipped with a conventional meat feeding device of belt conveyor-type, to do a continuous slicing work stably under the situation of softened fat by a temperature increase on the surface of chilled meat block with minus 5�� Cersius.

The Slicer for Pork Cutlets that Nippon Career Industry Co., Ltd. developed newly is capable of obtaining a stable thickness of meat without fail by means of following advantages:

- A meat block is surely fed by a swing movement of the unique swing shoot inclining at a 45 degree angle.

- A meat block is held so firmly by Pusher which generates only during the process of cutting that a stable thickness can constantly be obtained.

Furthermore, there is a positioning plate incorporated in the machine that receives the top end of the meat block.By moving and adjusting the positioning plate in a radial direction against a swing movement of Swing Shoot, an exact thickness can be determined, and thus the sliced meat with great precision and with an even thickness can be taken.

Exact cutting

Band Knife is used for an edged tool. As the meat block will be cut during being pushed down firmly to the round-shape positioning plate, even a softened surface portion of chilled meat can be sliced with great certainty.

Fine cut surface

While operating, a constant supply of water is made to both a surface of the cutting blade and its guiding groove. Then, the scraper cleanses the surface of the cutting blade and its guiding groove. Therefore, the cut surface of the meat is free from soiling by fat and roughening by grinding powder. The drain tank is standard equipment.

Also, a touching area of the Band Knife is so small that it minimizes the damage of its cut surface.

Minimum loss

As the pressure plate registered a patent is equipped, the slicing operation can continuously be done even when a volume of the meat block becomes small, and a high yield ratio can be obtained.

Minimum loss

As the pressure plate having been patented is equipped, the slicing operation can continuously be done even when a volume of the meat block becomes small, and a high yield ratio can be obtained.

Capable of continuous operation

Continuous feeding of the meat block from the back of the Swing Shoot made a continuous operation possible.

Enlarged cut width

This machine is capable of cutting three meat blocks with maximum width 150mm�~height 100mm simultaneously and also has a capability of cutting max. 70 times/minute (210 pieces/minute) with its adjustable swing frequency. Also, three meat blocks are separated each other by partitions and the finished goods are discharged with some intervals; thus the consecutive jobs are easy.

Excellent operability(Operation and cleaning)

Adjustment of thickness can be done by manual handling that seldom has troubles and it is easy to see owing to a digital display.

A cutting blade can easily be attached and detached as an automatic tension by air is used.

A simple monitoring device indicating abnormal positions is equipped.

One-touch connecting and disconnecting of the conveyor and the machine main body can be done by means of an inductive mounting system over a rail.

The conveyor belt itself can be mounted and dismounted on the spot.

A dust box and a scraper for the conveyor belt are equipped as standard.

The Pulley for Cutting Blade with Inter-lock, a safety cover at a cutting area and emergency stop-switches at three different locations, right, left and the backward are provided.

Blade Holding and Guide Plate with high strength and high durability

The groove of the Blade Holding and Guide Plate that guides the Band Knife is made of combined structure of a heat-treated tool steel, and the Blade Holding and Guide Plate can easily be replaced.

| Model | TS-490 |

|---|---|

| Power supply | 3-Phase 200V 1.5/2.2/0.2 kW�@ |

| Capacity | 3-row-cut 210 piece/minute |

| Tub Capacity | |

| Dimensions: (Width�~Depth�~Height) | 2100�~2600�~1500mm |

| Weight | 1550�@kg |

| Remarks | Dimensions of possible slicing material�F 160�iW�j�~100�iH�j�~600�iL�jmm Temperatures of possible slicing �F -2�`0��C.�iPossible until -5��C. depending on a water-processed condition�j Air supply source pressure�iIt is a little bit different depending on a shape of meat material, a consistency of meat like a toughness and a thickness of meat.�j Adjustable thickness of slicing�@�F1�`20�@mm Air supply source pressure�@�F0.5�`1.0�@MPa Air consumption volume�@�F400�@liters/min Water�FConnecting to a water piping ��The TS-490 is the order-made product that is manufactured according to users�f needs. Please contact us the details if required. |

For slices and end pieces as well.

"Correspond to every slicing!"

Realized High Yield Rate!

Diagonal-cutting can be done as well!

The meat in plus temperatures range can surely be cut!

The yield rate can be improved as joined meat is cut to the end with a pusher plate!

High efficiency can be achieved owing to consecutive supply of the raw material during the

operation!

Sliced meat can be arranged on the discharge conveyor in order!

��The attached/removed type diagonal-cutting device and the work table are options

| Model | AXY-200 |

|---|---|

| Power supply | AC200V 1.39kW |

| Capacity | 40 to 70 (changing every 5 times), max.140 pieces per minute on two lines discharge. |

| Tub Capacity | |

| Dimensions: (Width�~Depth�~Height) | 1080�~2275�~1165mm |

| Weight | 570 kg |

| Remarks | Max. material size : 1�`25mm Cutting dimensions(with partition) : W95(2-row)�~H20 to 100�~L600 Cutting dimensions(without partition) : W200�~H20 to 100�~L600 Sliceable temperatures(degree Centigrade) : Minus 1 degree C. to plus 5 degree C. (Plus 2 to 3 degree C. for proper temperatures.) Slicing method : Up & swing movement at meat feeding part Feeding system of meat : Forcible feeding by pressure board and belt conveyor Air pressure & amount : 0.5 MPs 260 liters/minute Option : Attached and removed type diagonal slicing device(AXY-200N)/Right and left working table for discharge conveyor |

��All specifications are subject to change without notice to improve the product.